Hilding

New member

- Joined

- Dec 6, 2017

- Location

- Sweden, v?rmland

So uuuuh I usually wanna finish things before updating, but uuuuuuh I keep making things more uuuuh "difficult" and never seem to quite finish.

So uuuuuuh here's an partial update since last.

Ever wonder why there are so darn many warning labels on things these days?

Idiots, that's why.

Following is the harrowing tale from inside the mind of one of these idiots.

We will also catch a glints as to why dentistry is so profitable, and why driving a small japanese sports car in the middle of a nordic winter is not the best idea, nor the worst.

The car has been great since the engine swap, noooo trouble what so ever.

But there has been some mystery as to why the heater core won't stop making bubbly sounds.

It's not uncommon at all after refilling the cooling system, usually it clears out in a day or two.

This time however, it did not.

Not wanting to face reality I tried several times to put the car in various slopes, reving it's little heart out to clear the bubbles. Which works, until the day after.

I also tried this:

I did recall vaguely that the manual says not to ever do this. But I did it anyway because I think I know better.

Then I did this as to not die from the fumes by running the car indoors, gotta think

It kind of worked, the rather heavy crank pulley (b21) almost flew off, that didn't stop me from trying again, then it did fly of and almost hit me in the face, which got me thinking.

And if I start to think I won't stop, which led me into trying to figure out why the car has been running on three cylinders when cold, a problem that had been escalating.

Looking at the sparkys made me think that there might be a stuck/not closing injector:

The injectors looked "rough"

Placeholder for image of dirty injectors that somehow Google Photos killed after I rotated it. I don't feel safe anymore.

There was rust and "gunk" in the injector rail:

Blew some brakeleen through the injectors using a sophisticated adapter

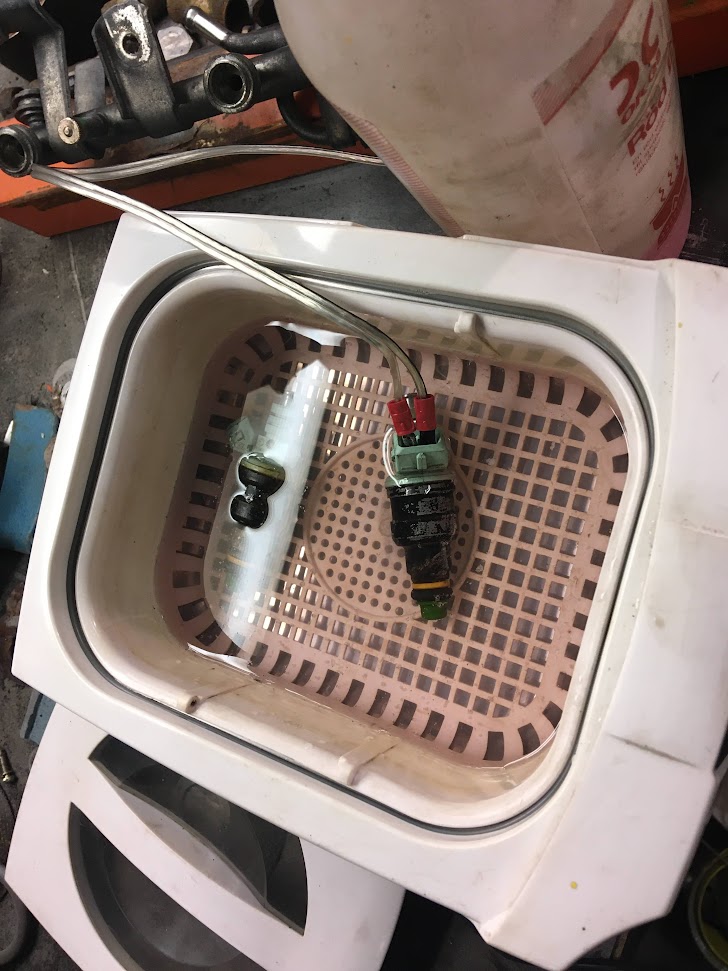

Then they bathed in a ultrasonic cleaner with 50/50 water/red ethanol whilst I furiously clicked the injector open:

S? clean, I ?ls? kleaned tche sparkys which I should replace b???t they have the vary c??l "R" on thiem.

I'm a sucker for **** like "R", "Turbo", "Cool stuff".

I also cleaned the rail the best I could and dared, blew through it with brakeleen and brushed the inside I could reach with a soft brush and 5-56.

At least no loose flakes left.

And huzzah! It runs well again.

I think you can clearly see the smooth idle in this picture:

The sharp observer may notice how I ignored the issue with the bubbly noise from the heater core, but reality kept at it and I soon noticed a lack of coolant, and alot of pressure even a day or two after it last ran.

So back inside we gooooo

I also have had some so called "slippage" on the clutch, and also that there was oil under the engine+gearbox

That's oil.

And since I have a new clutch for m90+deep flywheel that I originally meant to use with the m90+m40 setup on the original engine, I figured it was a good time to change the seal in the rear as I had to change the flywheel for the clutch.

I did not however want to remove the gearbox together with the engine (remember how I redo things after I've done something where it would have been a good idea to do the thing that I now need to do?).

So I made a stick.

And tried to flatten the ends with my pipebender-turned-hydralic-press

Don't be fooled, the press didn't work out, I had to do it in the vice.

aw yes it's already paying off

And wooosh, a stick to hold the gearbox, I couldn't have done that faster/simpler, nooo sireeeh

Maybe I'll leave it there after, it clears all the things

Here-we-go-again.jpg

So uuuuuuh here's an partial update since last.

Ever wonder why there are so darn many warning labels on things these days?

Idiots, that's why.

Following is the harrowing tale from inside the mind of one of these idiots.

We will also catch a glints as to why dentistry is so profitable, and why driving a small japanese sports car in the middle of a nordic winter is not the best idea, nor the worst.

The car has been great since the engine swap, noooo trouble what so ever.

But there has been some mystery as to why the heater core won't stop making bubbly sounds.

It's not uncommon at all after refilling the cooling system, usually it clears out in a day or two.

This time however, it did not.

Not wanting to face reality I tried several times to put the car in various slopes, reving it's little heart out to clear the bubbles. Which works, until the day after.

I also tried this:

I did recall vaguely that the manual says not to ever do this. But I did it anyway because I think I know better.

Then I did this as to not die from the fumes by running the car indoors, gotta think

It kind of worked, the rather heavy crank pulley (b21) almost flew off, that didn't stop me from trying again, then it did fly of and almost hit me in the face, which got me thinking.

And if I start to think I won't stop, which led me into trying to figure out why the car has been running on three cylinders when cold, a problem that had been escalating.

Looking at the sparkys made me think that there might be a stuck/not closing injector:

The injectors looked "rough"

Placeholder for image of dirty injectors that somehow Google Photos killed after I rotated it. I don't feel safe anymore.

There was rust and "gunk" in the injector rail:

Blew some brakeleen through the injectors using a sophisticated adapter

Then they bathed in a ultrasonic cleaner with 50/50 water/red ethanol whilst I furiously clicked the injector open:

S? clean, I ?ls? kleaned tche sparkys which I should replace b???t they have the vary c??l "R" on thiem.

I'm a sucker for **** like "R", "Turbo", "Cool stuff".

I also cleaned the rail the best I could and dared, blew through it with brakeleen and brushed the inside I could reach with a soft brush and 5-56.

At least no loose flakes left.

And huzzah! It runs well again.

I think you can clearly see the smooth idle in this picture:

The sharp observer may notice how I ignored the issue with the bubbly noise from the heater core, but reality kept at it and I soon noticed a lack of coolant, and alot of pressure even a day or two after it last ran.

So back inside we gooooo

I also have had some so called "slippage" on the clutch, and also that there was oil under the engine+gearbox

That's oil.

And since I have a new clutch for m90+deep flywheel that I originally meant to use with the m90+m40 setup on the original engine, I figured it was a good time to change the seal in the rear as I had to change the flywheel for the clutch.

I did not however want to remove the gearbox together with the engine (remember how I redo things after I've done something where it would have been a good idea to do the thing that I now need to do?).

So I made a stick.

And tried to flatten the ends with my pipebender-turned-hydralic-press

Don't be fooled, the press didn't work out, I had to do it in the vice.

aw yes it's already paying off

And wooosh, a stick to hold the gearbox, I couldn't have done that faster/simpler, nooo sireeeh

Maybe I'll leave it there after, it clears all the things

Here-we-go-again.jpg