Coupid

Active member

- Joined

- Sep 24, 2003

- Location

- Santa Barbara, CA

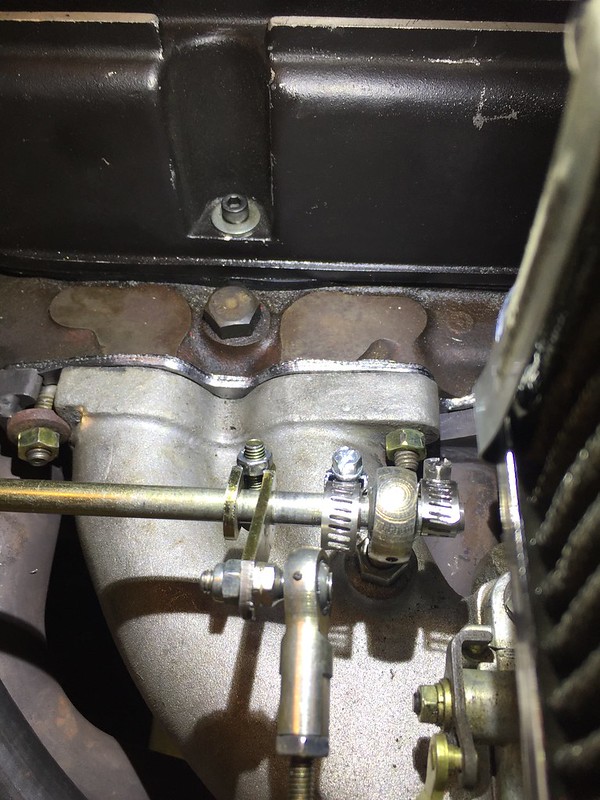

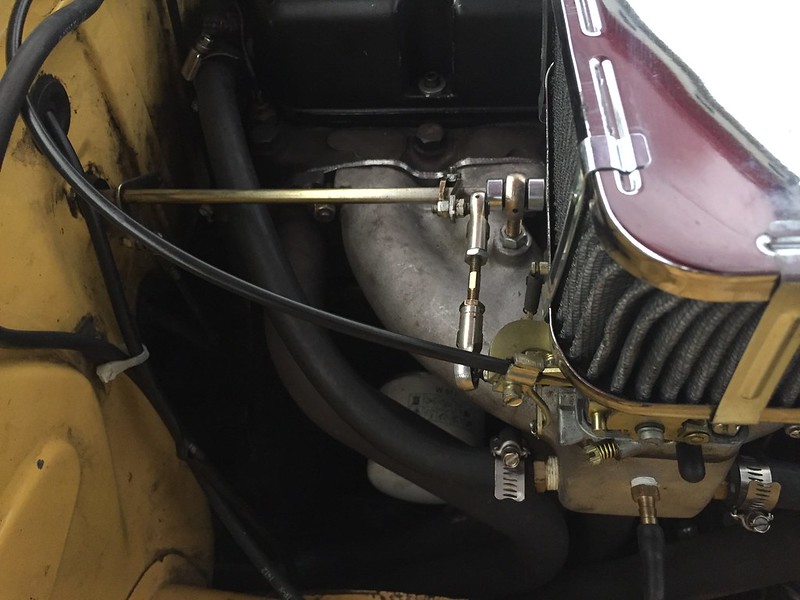

m46 will clear te trans tunnel i tink, m47 fitted in my 72 142, but i swapped to m90 and that big lump did not fit. 16v without turbo i would run the engine slanted. because you don't need al lot of room for the exhaust. and the inlet/carbs need the room.

good info! Did you mount the B20 straight up or angled with the M47? I'd need to run the B234 upright since I would use Yoshifab adaptors since I don't have a welder or the ability to fab up mounts.