TurboBricks Brand K-jet Fuel Pressure Test Equipment and Procedure

It is time to get back to the Bertone restoration and I knew that I was going to need more professional fuel pressure test equipment.

After searching all the various threads and stealing all the information I could this is the results of my efforts:

Upgraded version with hook to hang from hood. I used duct tape to hold the coat hanger hook in place until the JB Weld set.

It uses all standard Home Depot high quality professional fittings except for the valve and meter that were sourced from another US based supplier of Chinese hardware.

Pressure gauge: https://www.ebay.com/itm/253444469399?hash=item3b0277b297:g:U2YAAOSwObhctKcG

Valve: http://www.ebay.com/itm/1-4-Mini-Br...886?pt=LH_DefaultDomain_0&hash=item1c36162b86 or direct: https://www.directmaterial.com/Bras...tm_term=1100910235602&utm_content=Ad Group #1

Correct fuel hose clamps were from Harbor Freight.

The banjo fittings are 8mm and 10mm from my junk box as is the fuel hose.

Total cost: less than $20.

The 8mm banjo is connected to the top center port on the fuel distributor and the 10mm to the input to the Control Pressure Regulator (CPR). With the valve closed the fuel distributor regulated pressure is measured as the return is shut off. That should be in the 65 to 75 psi range depending on the fuel distributor specifications. The pressure can be adjusted by adding/removing shims to the distributor pressure regulator.

See this thread: http://forums.turbobricks.com/showthread.php?t=274908

With the valve in open position the CPR regulated pressure is measured. That should start off in the low to mid-twenties psi cold depending on the model of the regulator. After heating for 3-5 minutes the regulated pressure should be mid 40's to low 50's psi depending on the regulator specifications. Assuming that fuel distributor regulated pressure above is correct anything outside this range indicates a defective CPR.

There is a rebuild thread here: http://b2resource.com/PDFs/wurservicing.pdf

And a much more detailed description of its operation and assembly here (provided by Redwood Chair): http://www.jtresto.com/e21/WURServicing.pdf

Unless you repair very expensive Swiss watches for a living or a hobby I would suggest that you do not try to solve K-jet problems by opening the fuel distributor. It is a very precision bench calibrated device. But if you are tempted or just curious read this first:

http://www.cis-jetronic.com/public_doc/07.3-0997-06.pdf

An excellent explanation of the Lambda fuel management system, including the O2 sensor, the control module, the frequency valve operation and dwell adjustment can be found here thanks to keesue.

http://forums.turbobricks.com/showpost.php?p=5004662&postcount=35

An excellent discussion of K-jet overall operation can be found here: This link no longer works.

rl]http://www.k-jet.org/articles/information/k-jet-in-detail/[/url]

And the K-jet.org trouble shooting guide: This link no longer works.

http://www.k-jet.org/articles/infor...tp://www.ferrari400parts.com/kjetdownload.php

And the GreenBook itself here: These links no longer work

ttp://www.k-jet.org/files/greenbooks/TP30454-1_ci_system_part_1.pdf[/url] and

http://www.k-jet.org/files/greenbooks/TP30454-1_ci_system_part_2.pdf[/url]

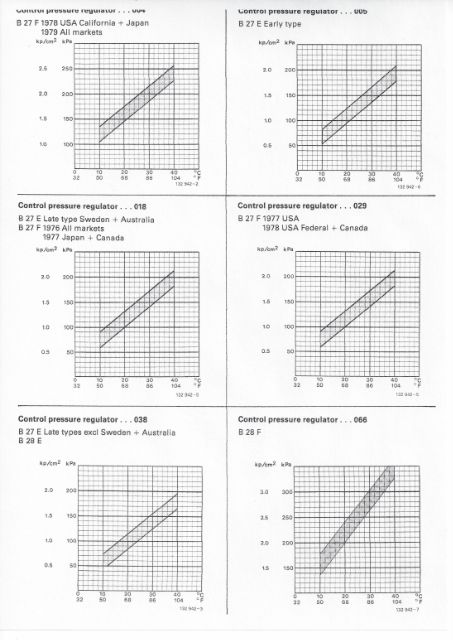

The CPR pressure charts for the B 27 - B 28 engines: http://forums.turbobricks.com/showpost.php?p=4815927&postcount=18

With the 8mm banjo connector connected to the cold start injector port of the fuel distributor, with the valve closed, the pressure to the injectors in operation can be read. Here things get a little more complicated. That measurement varies with throttle position operating on the air flow sensor and is more a function of fuel volume flow and frequency valve operation than dead headed pressure. But at least it can verify that there is fuel being supplied to the injectors.

After the fire repairs I have a number of 8mm banjo connectors to share in case anyone needs one.

The 10mm are harder to find as there is only a couple on each K-jet system. If you cannot find one off a JY car they are available here but not at TB pricing through Walmart: https://www.walmart.com/ip/2-Sets-1...ffe75b3a96e810497ca93abc67b36380&gclsrc=3p.ds

I would comment that the following post from one of our most knowledgeable, experienced, helpful and humorous members, now passed on to a better life is one of the greatest compliments I have ever received. May my friend TrickMick rest in peace.

It is time to get back to the Bertone restoration and I knew that I was going to need more professional fuel pressure test equipment.

After searching all the various threads and stealing all the information I could this is the results of my efforts:

Upgraded version with hook to hang from hood. I used duct tape to hold the coat hanger hook in place until the JB Weld set.

It uses all standard Home Depot high quality professional fittings except for the valve and meter that were sourced from another US based supplier of Chinese hardware.

Pressure gauge: https://www.ebay.com/itm/253444469399?hash=item3b0277b297:g:U2YAAOSwObhctKcG

Valve: http://www.ebay.com/itm/1-4-Mini-Br...886?pt=LH_DefaultDomain_0&hash=item1c36162b86 or direct: https://www.directmaterial.com/Bras...tm_term=1100910235602&utm_content=Ad Group #1

Correct fuel hose clamps were from Harbor Freight.

The banjo fittings are 8mm and 10mm from my junk box as is the fuel hose.

Total cost: less than $20.

The 8mm banjo is connected to the top center port on the fuel distributor and the 10mm to the input to the Control Pressure Regulator (CPR). With the valve closed the fuel distributor regulated pressure is measured as the return is shut off. That should be in the 65 to 75 psi range depending on the fuel distributor specifications. The pressure can be adjusted by adding/removing shims to the distributor pressure regulator.

See this thread: http://forums.turbobricks.com/showthread.php?t=274908

With the valve in open position the CPR regulated pressure is measured. That should start off in the low to mid-twenties psi cold depending on the model of the regulator. After heating for 3-5 minutes the regulated pressure should be mid 40's to low 50's psi depending on the regulator specifications. Assuming that fuel distributor regulated pressure above is correct anything outside this range indicates a defective CPR.

There is a rebuild thread here: http://b2resource.com/PDFs/wurservicing.pdf

And a much more detailed description of its operation and assembly here (provided by Redwood Chair): http://www.jtresto.com/e21/WURServicing.pdf

Unless you repair very expensive Swiss watches for a living or a hobby I would suggest that you do not try to solve K-jet problems by opening the fuel distributor. It is a very precision bench calibrated device. But if you are tempted or just curious read this first:

http://www.cis-jetronic.com/public_doc/07.3-0997-06.pdf

An excellent explanation of the Lambda fuel management system, including the O2 sensor, the control module, the frequency valve operation and dwell adjustment can be found here thanks to keesue.

http://forums.turbobricks.com/showpost.php?p=5004662&postcount=35

An excellent discussion of K-jet overall operation can be found here: This link no longer works.

rl]http://www.k-jet.org/articles/information/k-jet-in-detail/[/url]

And the K-jet.org trouble shooting guide: This link no longer works.

http://www.k-jet.org/articles/infor...tp://www.ferrari400parts.com/kjetdownload.php

And the GreenBook itself here: These links no longer work

ttp://www.k-jet.org/files/greenbooks/TP30454-1_ci_system_part_1.pdf[/url] and

http://www.k-jet.org/files/greenbooks/TP30454-1_ci_system_part_2.pdf[/url]

The CPR pressure charts for the B 27 - B 28 engines: http://forums.turbobricks.com/showpost.php?p=4815927&postcount=18

With the 8mm banjo connector connected to the cold start injector port of the fuel distributor, with the valve closed, the pressure to the injectors in operation can be read. Here things get a little more complicated. That measurement varies with throttle position operating on the air flow sensor and is more a function of fuel volume flow and frequency valve operation than dead headed pressure. But at least it can verify that there is fuel being supplied to the injectors.

After the fire repairs I have a number of 8mm banjo connectors to share in case anyone needs one.

The 10mm are harder to find as there is only a couple on each K-jet system. If you cannot find one off a JY car they are available here but not at TB pricing through Walmart: https://www.walmart.com/ip/2-Sets-1...ffe75b3a96e810497ca93abc67b36380&gclsrc=3p.ds

I would comment that the following post from one of our most knowledgeable, experienced, helpful and humorous members, now passed on to a better life is one of the greatest compliments I have ever received. May my friend TrickMick rest in peace.

Last edited: