Preliminaries... I have a 4r70w from a 2000 v6 stang installed behind a 302w in a 242. The engine is currently being controlled by a megasquirt 2 extra system.

drumroll.. sitting next to the car is an uninstalled microsquirt v3 whose purpose in life is to control said 4r70w.

I'm hopeful to have it wired up in the next week but I have never "tuned" a transmission before.

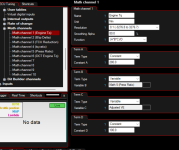

Anyone out there have relevant transmission tuning experience? I'm looking at the tunerstudio configuration page now and there's quite a few blank windows. I downloaded someone else's tune file from msextraforums but still have questions...

The Questions

I suppose I'll have more questions once the thing is running but any pointers/advice beforehand will be appreciated.

drumroll.. sitting next to the car is an uninstalled microsquirt v3 whose purpose in life is to control said 4r70w.

I'm hopeful to have it wired up in the next week but I have never "tuned" a transmission before.

Anyone out there have relevant transmission tuning experience? I'm looking at the tunerstudio configuration page now and there's quite a few blank windows. I downloaded someone else's tune file from msextraforums but still have questions...

The Questions

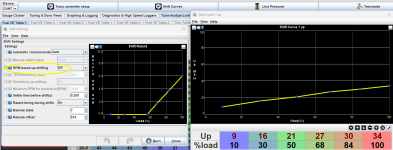

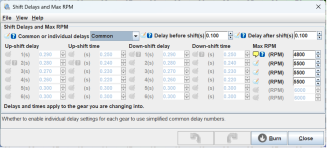

- How do I go about setting up a shift curve? Just copy/paste what someone else has and roll with it?

- How do I know what line pressure curve that the transmission needs? This is a mostly street car (maybe 250hp) that will very rarely see the strip.

- What are recommended lockup settings for the converter?

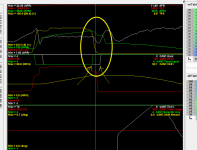

- I get tuning air fuel ratios and VE bins, but what exactly am I looking for when I am logging data from the microsquirt?

I suppose I'll have more questions once the thing is running but any pointers/advice beforehand will be appreciated.